What kind of a machine is a 3D printer?

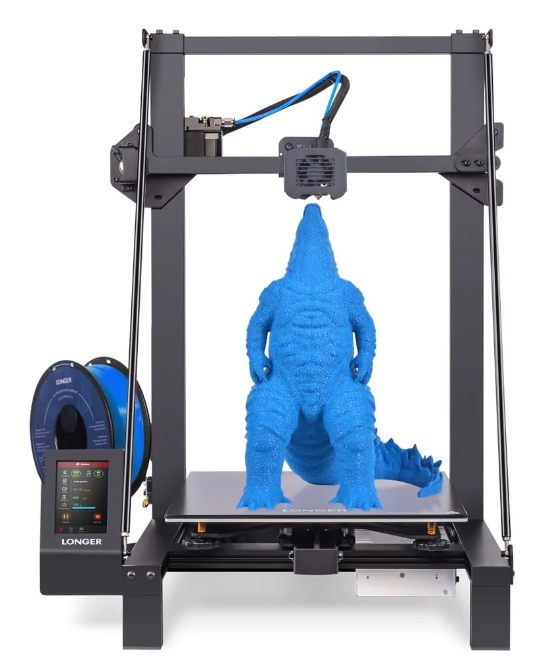

A 3D printer is a type of machine that is used to create physical objects by building them up layer by layer from a digital file. It works by using a process called additive manufacturing, in which successive layers of material are added to create an object. The material used in 3D printing is called a filament, and it can be made from a variety of substances like different plastics, including parts of other materials, like metals, wood, and ceramics. 3D printers are used in a wide range of applications, including prototyping, manufacturing, and art. They can create objects in a variety of shapes and sizes, and they can be used to make everything from toys and tools to medical implants and architectural models.

A 3D printer uses filament to print, like a normal printer uses ink.

A 3D printer filament is a material that is used in 3D printing to create objects by laying down successive layers of the filament. It is essentially the “ink” used in a 3D printer, similar to how regular printers use ink or toner. 3D printer filaments come in a variety of types and materials, such as ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), PETG (Polyethylene Terephthalate Glycol), and nylon, among others. The type of filament used depends on the desired properties of the finished product, such as strength, flexibility, and durability. The filament is fed through the printer’s extruder head, where it is melted and then deposited onto the print bed in precise layers to build up the object.

The 3D Printer extruder, what is it?

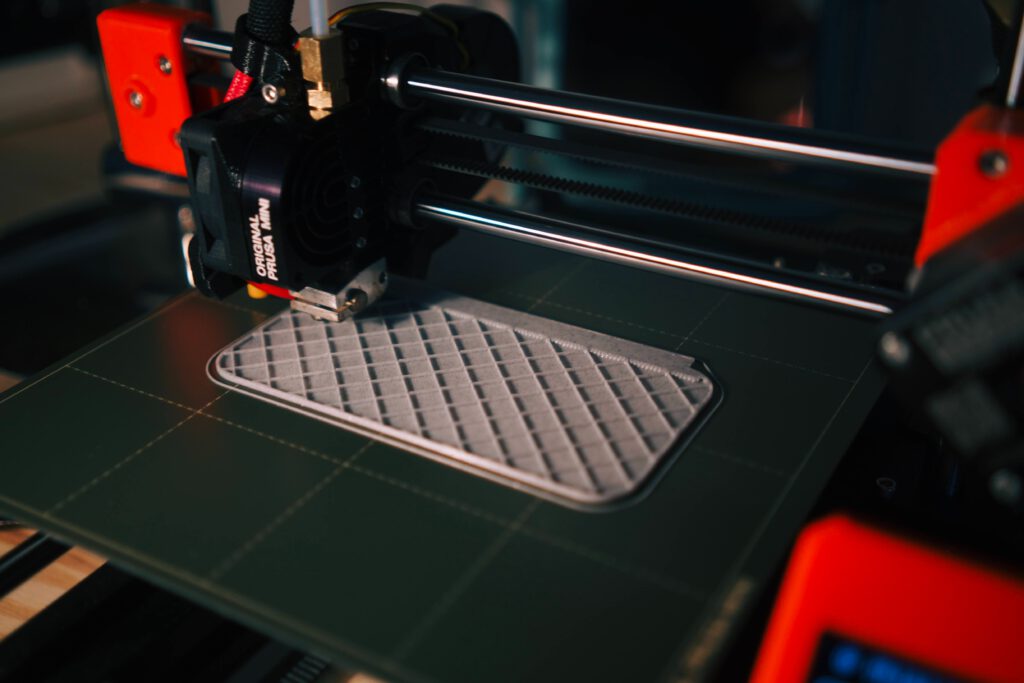

The extruder is the component of the 3D printer that pushes the molten plastic through the nozzle to create the desired shape. The extruder motor works by turning a small gear that moves the plastic filament through the extruder and out of the nozzle. It is an essential part of the 3D printing process, as it allows the printer to accurately control the flow and placement of the plastic material to create the desired object. The extruder is typically controlled by the 3D printer’s control board, which receives commands from the printer software and sends the appropriate signals to the motor to move the filament as needed.

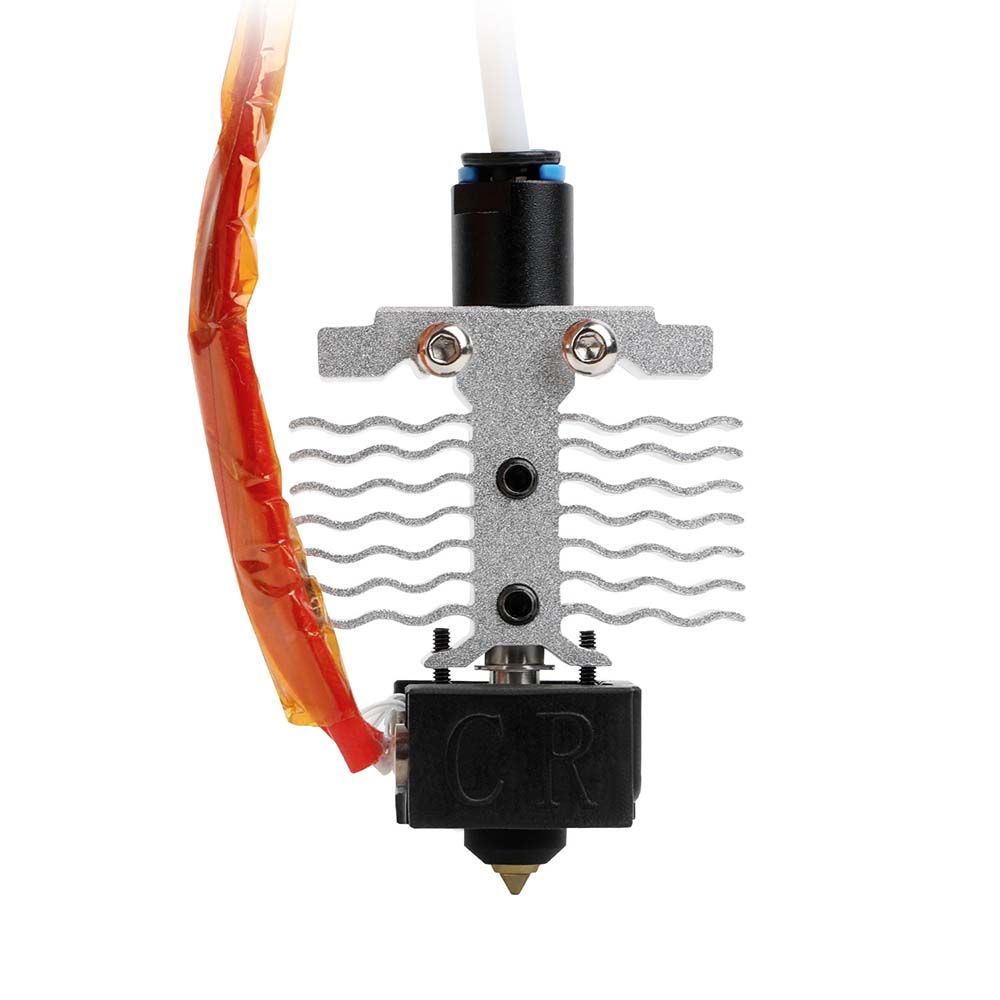

The Hot End melts the plastic

A 3D printer hot end is the part of the printer that melts and extrudes the filament (the plastic material used to create the 3D object). It consists of a heating element that heats the filament to a high temperature and a nozzle that pushes the melted filament out onto the build platform. The hot end is controlled by the printer’s firmware and can be adjusted to different temperatures depending on the type of filament being used. It is a crucial part of the 3D printing process as it determines the quality and accuracy of the printed object.

What is a Nozzle?

In 3D printing, the nozzle is used to extrude a thin layer of melted plastic or other material onto the printing bed. The nozzle is attached to the extruder, which heats and melts the material, and is moved around the bed by the 3D printer’s motors to trace the desired shape. The size of the nozzle determines the thickness of the layer being printed, and can be changed to adjust the precision and speed of the print. Some 3D printers also have multiple nozzles to allow for different materials or colors to be printed simultaneously.

There are several differences between different nozzle sizes used for 3D printing:

- Resolution: Nozzle size determines the resolution of the final print. A smaller nozzle size allows for more detailed prints, as it can produce finer layers and more precise details. On the other hand, a larger nozzle size results in coarser prints with less detail.

- Printing speed: Nozzle size also impacts the printing speed of a 3D printer. Larger nozzle sizes allow for faster printing as more material can be laid down in a shorter period of time. However, this comes at the cost of reduced resolution and detail.

- Material compatibility: Different nozzle sizes may be compatible with different materials. For example, smaller nozzle sizes may be more suitable for printing with softer materials, while larger nozzle sizes may be better suited for printing with harder materials.

- Printer compatibility: Some 3D printers may only be compatible with certain nozzle sizes. It is important to check the specifications of your printer to ensure that you are using the correct nozzle size.

- Cost: Nozzle sizes can vary in cost, with smaller nozzle sizes generally being more expensive due to their increased precision and detail.